Inspiring ways to cut costs and CO2

How FlexMax® works for you!

FlexMax® doubles your load on each pallet place plus offers you the chance to maximally use floor space during transport. Simpler and faster than ever before.

FlexMax® delivers savings of up to 30% or more on your annual transport costs with the bonus of a secure load and a greatly reduced risk of damage.

Why FlexMax?

- Two loaded pallets on 1 pallet place

- Massive savings on transport costs

- Solid as a rock

- Protects goods from damage

- Flexible and efficient load factor

- No more problems with annoying ‘last pallets’ that ‘must go’.

How simple?

- Two piece unit

- Push-in frames

- Frames are identical

- Light frames

- Easy to handle

- Loadable from all sides

- Return on any empty pallet

More

- Integrated straps

- Suitable for both Euro and Block pallets

- Dynamic stackload 600 kg extra

- No need for expensive packaging

- Reduces logistic (fixed) costs per product

- Considerably reduces CO2 emissions

How customers cut transport costs by at least 30%!

Our customers actually experience savings of at least 30% on their transport costs. By increasing load capacity, saving on fuel and road tolls, minimizing damage and reducing the need for expensive packaging, APS cuts even more from your main operational costs.

Moreover, no additional investments or adaptations to your transport equipment or warehousing systems are necessary. The only change needed is a change to your operational guidelines and instructions.

Smart ways to use wasted space

By doubling load on

same pallet place

Doubling pallet loads with FlexMax drastically reduces the number of transport vehicles needed.

By stopping to order trucks

for last pallets to go

Doubling pallet loads with FlexMax makes extra truck for last-pallets-to-go fully superfluous.

By doubling load on same

floor space of special

transport vehicles

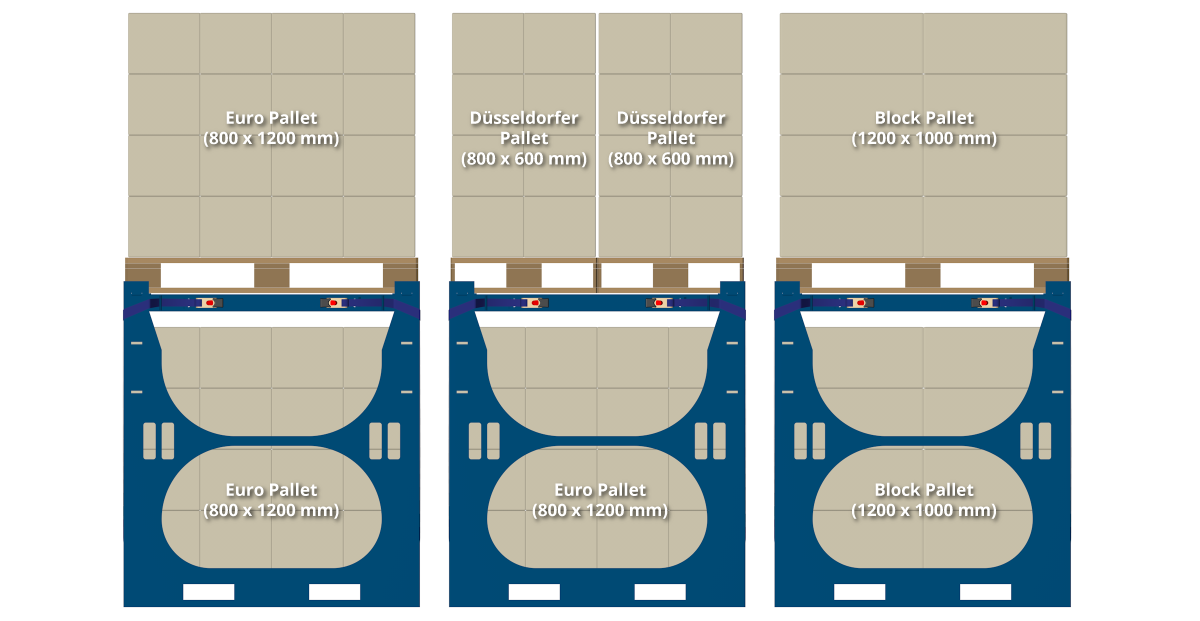

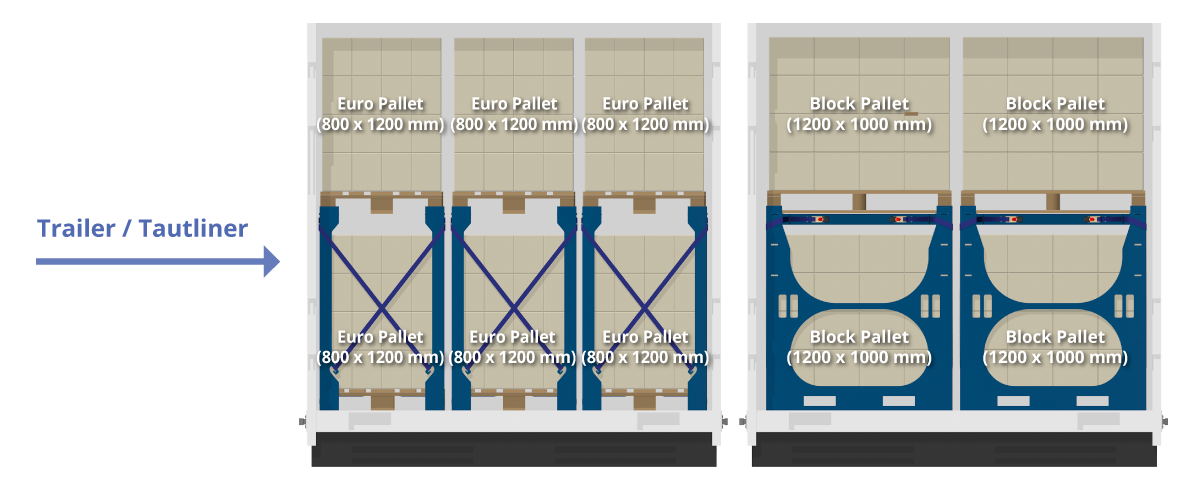

Double stacked pallets are now loadable from all 4 sides. This enables a maximised number of pallets in reefers, containers and on flatbeds.

From wasted space to extra profit

A second fully loaded pallet onto the same pallet position right up to roof height in your transport vehicle. That’s how APS is turning space into profits. By utilizing space that would otherwise be lost, APS Pallet Load Maximizers increase the load per trip and cut your costs dramatically.

There is an APS Pallet Load Maximizer for nearly every type of load – even products that are normally considered to be non-stackable. Whether you are transporting FMCG, automotive or vulnerable products like pharmaceuticals, food or even delicate electronics, APS has the right solution to help you turn wasted space into profits.

More savings

Reduce transport damage

Why risk damaged goods because they aren’t stowed effectively? FlexMax makes the difference. FlexMax gives extra protection and firmly secures your goods during transportation.

Both bottom and upper pallets are firmly bound together by tough cross straps on both sides. Thorough tests conducted by Tüv demonstrated the strength of AP Stacking’s pallet load maximizer FlexMax. Test it for yourself. Hire or buy a few, 10 or 50 FlexMaxes and make all tests you want. You will be positively surprised with what you see.

Load faster

Slotting the two FlexMax frames into the bottom pallet is a split second operation. Both FlexMax frames are identical and they can be placed on either side of a pallet. In no time at all you’re ready to load up to 600 kilos extra on a pallet above.

FlexMax enables the fork lift operator to place up to 4 fully loaded pallets in one go straight into a truck, trailer or container. Access to the fully loaded pallets is from whichever side the fork lift operator chooses so you save time, reduce warehouse traffic and minimise collision risks.

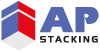

Stacking possibilities

Pallet loading places

Conveniences for users

Doubling load on

same floor space

Fewer forklift movements needed gives lower risk of collision damage

Loadable from

all 4 sides

Maximum use of floor space in transport vehicles like reefers, containers and flatbeds

Fast & Simple

handling

1. Two frames only

Easy to manage

2. Identical frames

No risks on mistakes

3. Push-in frames

Simply push frame into bottom pallet

Dynamic

stackload

600 kg extra

Extremely strong

cross straps

– Secures both pallets firmly

– Protects goods from damage

– Appreciated by customers and own management

Return FlexMax on

any empty pallet

No extra equipment necessary

More information for users

Restricting CO2

emissions

Considerable restriction of CO2 emission

Each frame features

a unique number

Easy to manage and control

Suitable for all common

pallet formats

Euro pallets, Block pallets, Düsseldorfers

Worldwide patent

Unique solution worldwide

Extra management benefits

Reduces definitely risk

of damage claims

Firmly bound together by ultra strong straps protect your goods to the max